Introduction

1. Features:

1.1. Reasonable mechanical structure, stable running and get higher speed, also easier for maintenance.

1.2. High precision assembling and debugging.

1.3. Accurate weighing, using screw auger weighing, with very high speed and good accuracy.

1.4. PLC control, color touch screen, servo motor, very easy to operate.

1.5. Full automatic auger weighing, bag forming, filling, sealing, coding, counting, most labor saving equipment.

1.6. High quality stainless steel, suitable for GMP, good for food packaging with high standard.

1.7. Low noise

2. Parameter list:

| Model | F420 | F520 | F680 |

| Film width | Max 420mm | Max 520mm | Max 680mm |

| Bag length | 80-300mm | 80-380mm | 100-450mm |

| Bag width | 60-200mm | 100-250mm | 150-320mm |

| Filling weight | 10g-2000g | 10g-4000g | 10g-6000g |

| Filling volume | Max 2500ml | Max 6000ml | Max 10000ml |

| Capacity | 5-50bags/min | 5-50bags/min | 5-50bags/min |

| Electricity | 220V, 50/60Hz, 3KW | 220V, 50/60Hz, 4KW | 220V, 50/60Hz, 5KW |

| Overall size (mm) | 1400*1200*1600 | 1800*1200*1650 | 1500*1400*1850 |

| Weight | 550kgs | 650kgs | 800kgs |

3. Application:

This automatic F420 F520 F680 Vertical Powder Pouch Packing Machine is used for packing many different products like milk powder, seasoning powder, baking powder, protein powder, coffee powder, wheet flour, medicine powder, chemical powder, and other powder products.

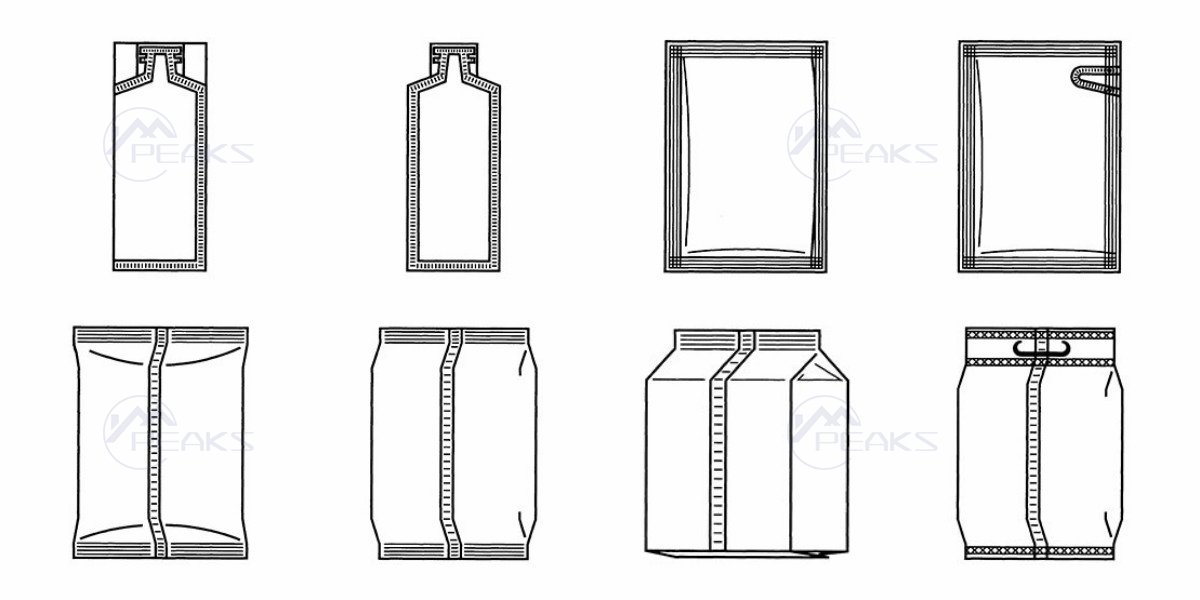

4. Bag Shape:

Pillow sealing bag / back sealing bag, gusset stand bag, doypack bag and etc.

5. Optional Function:

5.1. Punching device for round hole or Euro slot.

5.2. Linking bag device

5.3. Stand bag device, for plug in at bag bottom.

5.4. Servo motor on horizontal sealing parts.

5.5. Special device if you use single layer PE film.

5.6. Nitrogen inflation device.

6. Other devices:

6.1. Metal detector

6.2. Weight checker

6.3. Nitrogen generator

6.4. Finish product conveyor